Defining CAM templates: CAM Tools

EngView CAM tools drive machine instruments. Click

here to learn more about them.

What are CAM tools

In Prinect, CAM tools

are representations of how the physical instrument on the sample-producing

machine processes the objects as they come from the 1up drawing. Because

of this, wherever in this document you read "CAM tool" or

"tool", read it as "instrument processing mode".

You define a CAM tool by setting the properties that you want the

instrument to process. defined by properties that

Types of CAM tools

CAM tools can be:

- Primary. This is the processing mode that the instrument

uses most often.

- Child. A child tool is a modification of its parent

primary tool. Normally, it has most of the primary tool's properties

and settings, but some of its settings have been modified to serve

specific functions. For example, You can create child tools only

for an existing primary tool.

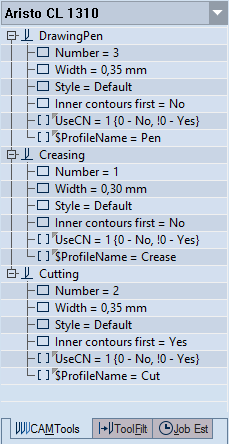

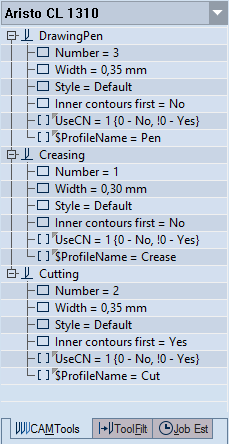

Where can I see them?

How CAM tools process tool paths

CAM tools process the tool path in the top-down

order in which they are sorted in the CAM template. The tool path

of the topmost tool is generated first, followed by the tool path

of the one below it, and so on. Prinect generates

separate optimized tool paths for each of the primary CAM tools and

processes these tool paths according to the top-down order in which

the tools are defined in the CAM template: the tool path of the topmost

tool is generated first, followed by the tool path of the one below

it, and so on. Prinect then links

the individual tool paths.

You might need to processes section of a

tool path with properties whose values are dfferent from those in

the primary tool. In this case, you create child tools. These inherit

the majority of the properies and their values of the parent tool,

but different values for others. Child tools appear directly below

their parent primary tools in the tool tree and are processed immediately

after them. Consider two examples: Example 1: A laser beam used for

cutting a dieboard may be used also for engraving the bridges along

the tool path. This removes the necessity of removing and readjusting

the beam, and then running it again along the tool path. By using

a child tool — which is a different mode of processing — an instrument

processes the same tool path in different work modes. Example 2: A

cutting tool can be used for cutting through a design completely and

also for executing half-cuts as in kiss cuts.

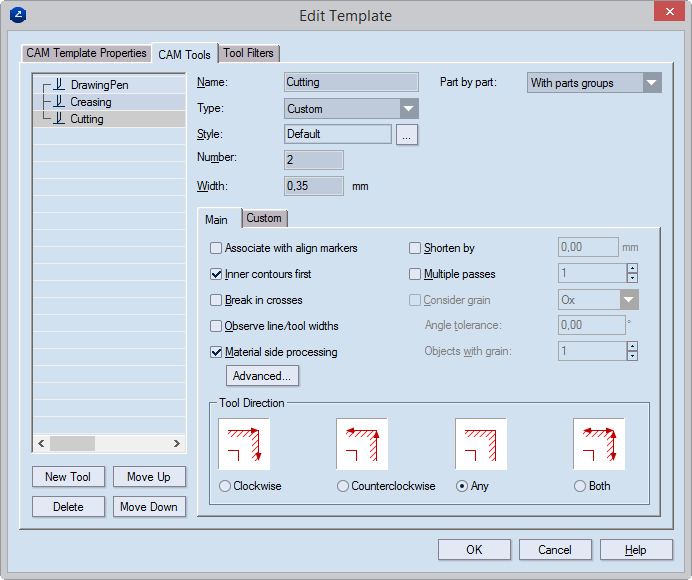

How do I define CAM tools?

NOTE: The procedure that follows tells

you how to create both primary and child CAM tools. To create a child

tool, in the tree structure in the left area, click a primary tool, and

then click New Tool Then proceed with defining the child tool.

======================

======================

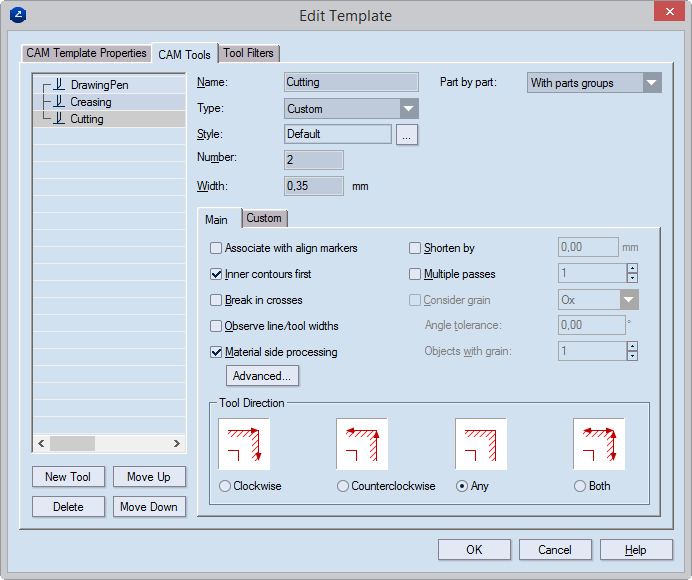

Name Type a name for the tool. It will appear (1) in the

tree structure on the right and then (2) in the CAM Tools tab of the CAM

drawing.

Type Set a type for the tool. Preset types include Router,

Laser beam, Water jet, Cutting knife, Creasing wheel, V-cut, Matt cut,

and Pen. Custom lets you set your own type.

Style Click the browse button  to select

the style of the objects that the instrument will process.

to select

the style of the objects that the instrument will process.

NOTE: "Default" means that no

style is selected. Use "Default" if you want to set a color

to a certain object type. This will not associate the instrument with

any particular style.

Number Type the number of the tool as corresponding to

the consecutive numbers of the instruments on the actual machine. NOTE:

You can change the tool number later, when you generate the NC script

file in the NC Generation Properties dialog box.

Width Set the physical width of the processing tool.

Part by part (Applies for CAM drawings generated

from layout drawings for which the part-by-part

processing rule has been set.)

Before part groups The tool will process the objects associated

with it — in the layout parts and those placed additionally — before processing

all other objects. NOTE: If this option is set for multiple tools in the

CAM

template, Prinect starts

one tool at a time in the top-to-bottom order set in the template.

With part groups The tool will process the objects associated

with it according to the part-by-part

processing rule. Objects placed directly in the layout drawing (they

do not belong to any layout part) will be processed last, after the objects

in the layout parts have been processed.

After part groups The tool will process the objects associated

with it — in the layout parts and those placed additionally — after all

other objects have been processed. NOTE: If this option is set for multiple

tools in the CAM

template, Prinect starts

one tool at a time in the top-to-bottom order set in the template.

The Main tab

Associate with align markers Associates the tool with align

markers, if such have been placed. Such can be, for instance, cut or creased,

depending on the tool with which they are associated.

Inner contours first Generates a tool path for which the

current tool starts from the inner objects. For example, if you make a

CAM sample of a packaging box with an inscribed ellipse in one of the

sides, cutting the outer contours first would leave the cutting of the

ellipse for the end of the tool path. As a result, the sheet will not

hold steadily on the samplemaking machine.

Break in crosses (Applies to the points where different

objects intersect.) To produce the optimal tool path, Prinect may choose

to shift the tool path's trajectory at the point where two objects intersect.

Observe line/width tool widths Takes into account the difference

in width between a tool whose width is smaller than the width of the object

to be processed, and makes additional runs of the tool so that the necessary

width is processed. For example, if the object is 6pt wide and the tool's

width is 2pt, the width of the resulting object will be less than the

6pt needed. In this case, the tool will make additional runs to process

the needed 6pt width.

Material side processing Sets properties for processing

of the material. These include (1) the side on which the cutting will

be done, (2) the lead-in and lead-out settings, and (3) the directions

of processing for the inner and outer sides. To edit these settings, click

Advanced, and then use the dialog

box that appears.

Shorten by Shortens the creasing objects by a certain distance,

so that the creasing wheel stops before it reaches the end of a creasing

lines. This prevents damaging creasing regions that lie next to creasing

lines. In the edit box on the right, enter the distance, in the current

metric units, by which you want to shorten the creasing objects.

Multiple passes The processing instrument performs several

passes on creasing objects. Enter how many times you want the creasing

instrument to pass along these objects. Value range: [0–3]. TIP: This

technique is very useful when processing a harder material. The creasing

objects are processed several times by the creasing instrument, which

ensures that later they are easier to fold. Type how many times you need

the instrument to pass along a tool path section. You can make the Prinect visualize

in how many times the instrument has passed along a tool path section

(use the Multi-pass count marker check box).

Consider grain Sets if the grain direction goes along the

x-axis or the y-axis.

TIP: When choosing the grain direction,

consider how the sheet is placed.

Angle tolerance Sets the maximal angle by which the creasing tool

should be allowed to veer off from the grain direction as measured against

the horizontal and vertical axes.

Objects with grain Sets a special number of creases for

the objects processed with grain direction. Usually this number will be

smaller than the number in Multiple crease. In this way, you can

use a different number of passes for the creasing objects processed along

the grain and the ones processed against the grain. Value range: [0–3].

Tool Direction

Clockwise Processes the outside contour clockwise.

Counterclockwise Processes the outside contour counterclockwise.

Any Lets Prinect choose

the processing direction — clockwise or counterclockwise.

Both Processes the contour both clockwise and counterclockwise.

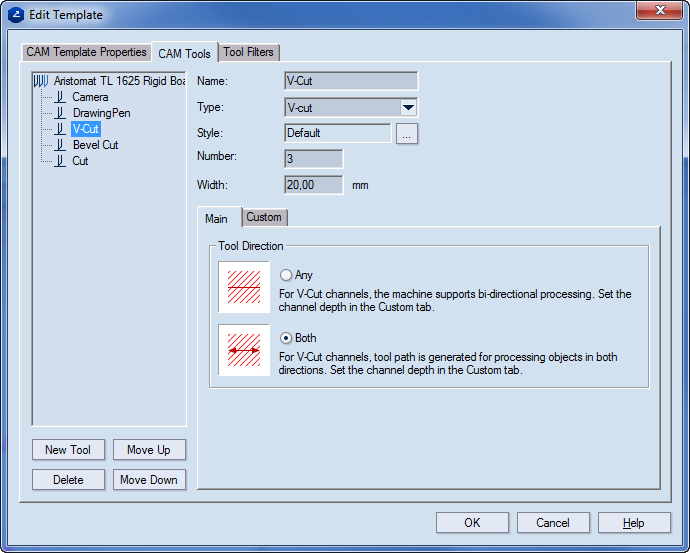

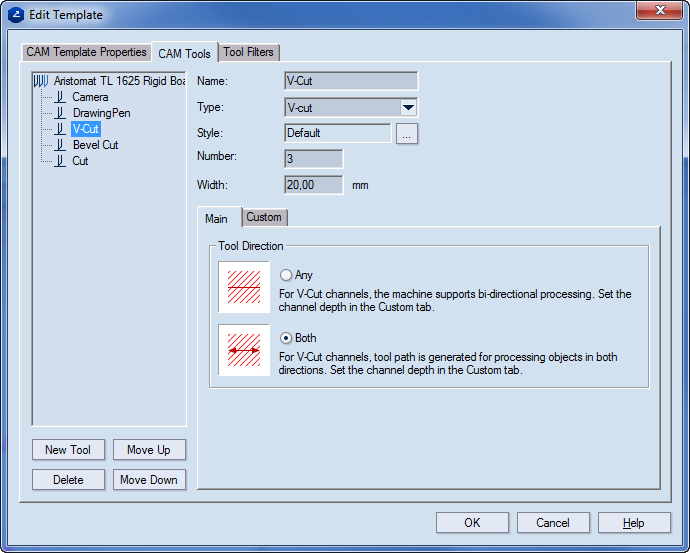

Editing V-Cut settings

Settings for V-Cut jobs differ from those for

the other CAM instruments.

Tool Direction

Any. Optimizes the tool path automatically. To set the channel

depth, click the Custom tab. NOTE: The reverse V-Cut move does not need

to follow immediately the forward one.

Both. The machine carries out both the forward and the reverse

moves.

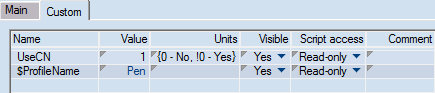

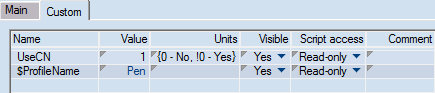

The Custom tab. You create the properties in this tab while you are setting the properties

of the machine. Here you can only edit their values as you need them

for the job in hand.

Name (Read-only) Displays the name of the custom property.

Check the custom properties that you want the child tools to inherit from

their primary tools.

Value Sets the value of the property.

Units Sets the measurement units of the value.

Visible Tells EngView whether to display the property in

the tabular area of the CAM Tools tab. The options are "Yes"

and "No".

Script access Sets how the script will handle the tool's

Value setting. The options are:

| Read-only |

The script uses the value of the property as it is defined

in the CAM template. No changes are made to it during the job. |

| Local Only |

During the job, the script dynamically makes changes to the

value of the property. These changes are lost after the job has

been completed. |

| Committable |

During the job, the script dynamically makes changes to the

property value. When the job is completed, the changes are saved

to the CAM template and apply to the next job. |

Comment (Optional) Type any relevant information about

the property.

Tool Optimzation (glass engraving)

You can make each instrument begin its course from the machine's starting

point. That is, when a tool has completed its course, the next tool starts

again from the machine's starting point, not from the nearest point of

the course of the next tool. Although the route that the instrument covers

is longer and may take more individual passes, it ensures greater precision.

This technique is especially applicable in glass engraving, as it ensures

highest-quality processing.

To reset the tool optimizer, create a custom property in the Custom

tab.

| Custom property and value |

What it does |

| StartFromZeroPoint = 0 |

The next tool starts from the point that's nearest to where

the last tool completed its course. |

| StartFromZeroPoint = 1 |

Each tool starts from the machine's starting point. |

to select

the style of the objects that the instrument will process.

to select

the style of the objects that the instrument will process.